$7M

WORTH OF

EQUIPMENTS

80+

Machines

300+

Workforce

14

Printing

Unit Setup

8M

Boxes Per

Annum

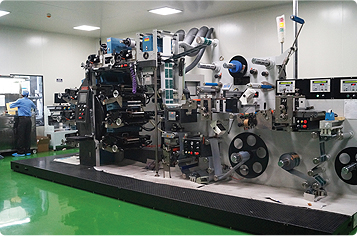

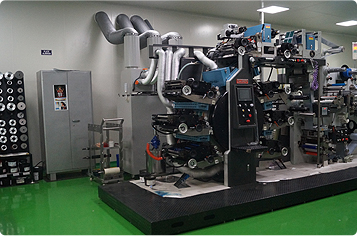

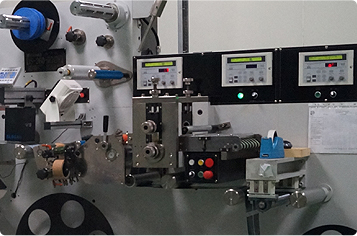

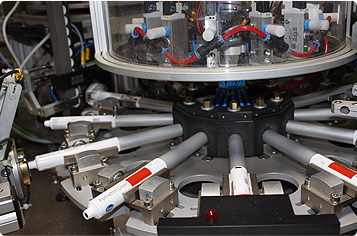

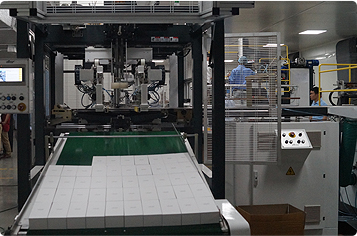

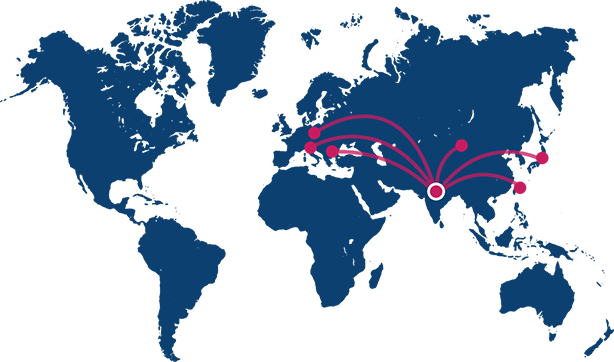

PRPL houses avant-garde machinery and systems from Germany, Switzerland, Bulgaria, China, Taiwan, Japan, India that meet with the highest certifications to ensure the best value for clients via every product that leaves our doors. As an innovative packaging company, we strive hard to give the best quality to our clients in every endeavor. We own a $7mn ( INR 50Cr+ worth) state-of-the-art infrastructural unit with all the required equipment and machines to accommodate any size and type of demands.

We have fully automatic equipment, over 80 machines whose entire list can be downloaded here. We have minimum 3 lines for each process, enabling adequate contingency planning in case of a down time or breakdown on any machine. Our 300+ workforce with both skilled, and experience professionals follow a rigorous training and upgradation program, while ensuring timely preventive maintenance as well as breakdown redressal of machines.